Comparison: Fiberglass vs Timber

Pultruded glass fiber reinforced structural shapes and plate have a number of significant advantages over timber in many structural applications. Pultruded fiberglass will not rot or decay and is not susceptible to insect attack. Unlike wood, fiberglass requires no environmentally unfriendly preservatives or repellants, does not absorb any significant amount of water and is consistent in strength and appearance piece-to-piece (no culling). Pultruded fiberglass is stronger, more rigid and lighter weight than structural timber.

Is pultruded fiberglass a better choice for your application? Consider the point-for-point comparison below.

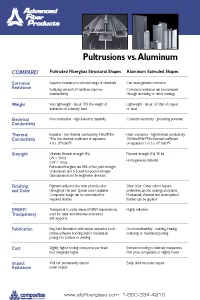

Comparison: Fiberglass vs Aluminum

Pultruded glass fiber reinforced structural shapes and plate have a number of significant advantages over aluminum extrusions. Pultrusions are electrically and thermally non-conductive, impact resistant, highly corrosion resistant and EMI/RFI transparent.

Is pultruded fiberglass the best material choice to meet the needs or requirements of your application? Features of both pultruded fiberglass structural shapes and aluminum extruded shapes are compared on a point-for-point basis below.

Comparison: Fiberglass vs Steel

Unlike Steel which will rust when exposed to weathering and chemicals, fiberglass structural shapes are highly corrosion resistant. Features of both pultrusions and steel structural shapes are compared on a point-for-point basis below.

| AFP Fiberglass | Steel | Aluminum | Timber | |

|---|---|---|---|---|

| Corrosion Resistance | High | Low | Medium | Low |

| Strength | High | High | High | Low |

| Weight | Low | High | Low | Medium |

| Finishing | Easy | Hard | Hard | Moderate |

| Conductivity | Low | High | High | Moderate |

| EMI/RFI Transparency | Yes | No | No | Yes |

| Maintenance | Low | Medium | Medium | High |

| Impact Resistance | High | Medium | Low | Low |

| Dimensional Stability | High | Low | Low | Low |